Fire Inspection Management Software

Inspection Manager

Inspection Manager helps fire protection contractors conduct faster, more accurate fire inspections of fire alarms, fire extinguishers, fire sprinklers, fire suppression systems, and other fire systems to reduce risk and drive more revenue.

Get a DemoTrusted by 1300+ Happy Customers

See How Contractors Use ServiceTradeStreamline Operations

Fire Inspection Software

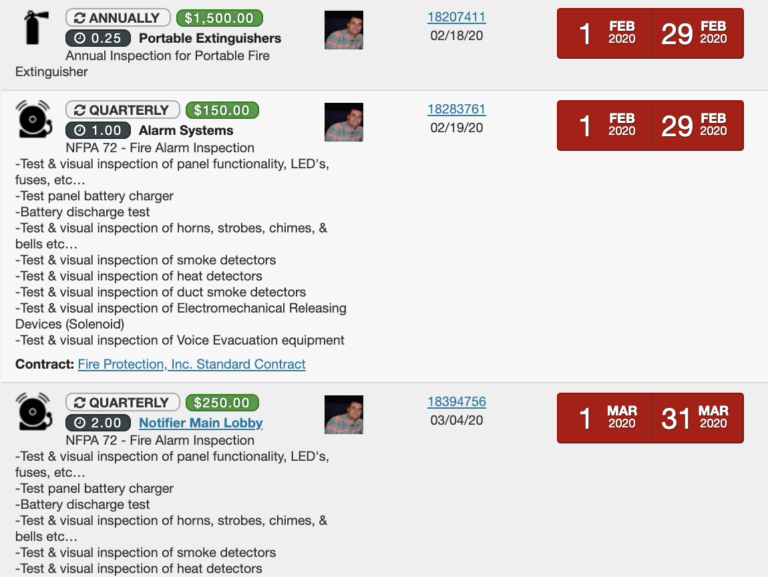

Never miss an inspection and email every inspection report and deficiency repair quote from ServiceTrade to meet code requirements.

The best fire inspection software reduces risk by ensuring that technicians perform accurate inspections, safeguarding the company with a digital paper trail of its inspection data, staying in step with NFPA inspection guidelines, and creating and sending proper inspection reporting.

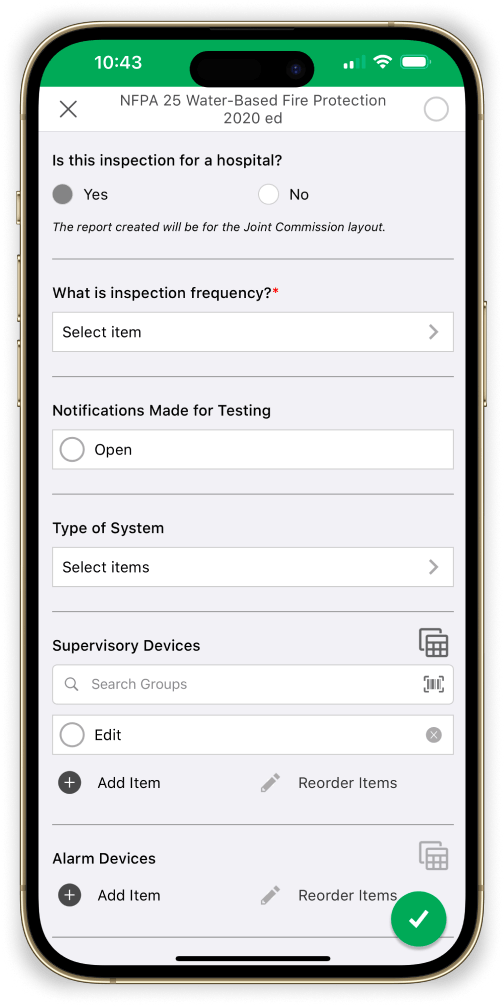

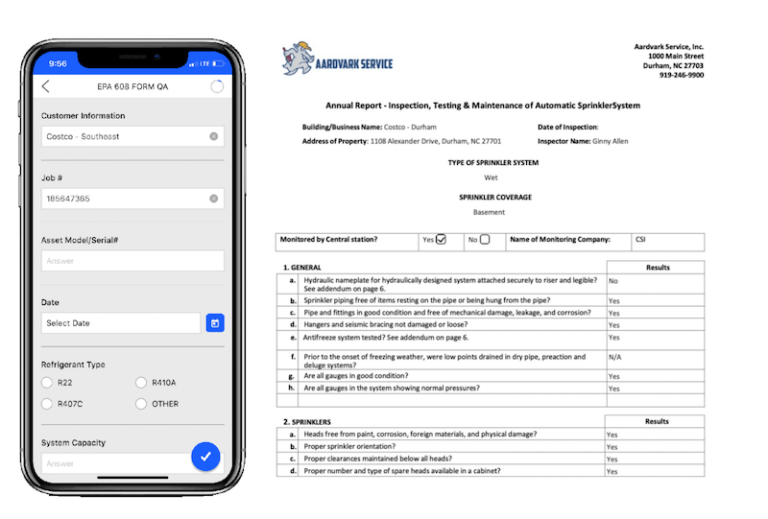

Provide technicians with NFPA inspection forms on their mobile devices that guide them through complete inspections.

Digital inspection forms streamline processes, speed up inspections, waste less time on double data entry, and eliminate the headaches of lost paperwork and reinspections.

Use our library of NFPA code-compliant inspection forms that are always up to date.

Inspection Manager’s NFPA code-compliant forms eliminate uncertainty if inspection forms are up to code and produce reports that meet AHJ and customer inspection reporting requirements.

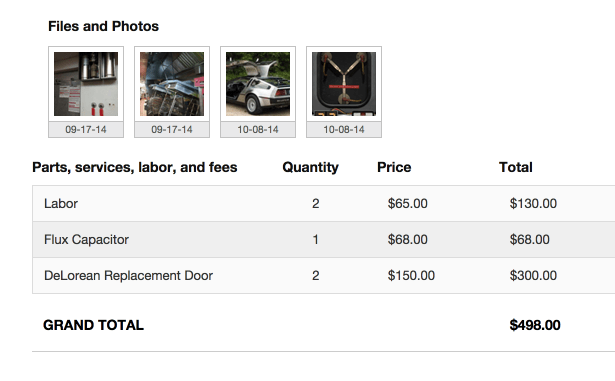

Report more deficiencies and turn deficiency and inspection data into repair quotes to create more pull-through work and eliminate potential fire hazards.

ServiceTrade’s workflows help technicians capture more deficiencies and make it easier for the office to send quotes to repair the problem and earn more high-margin repair revenue.

Provide an online portal for customers to download inspection reports, approve open quotes, and pay their invoices.

Most people prefer going online to find all the information they need in one place, which reduces the number of chaotic on-demand customer calls to your team.

Simple Pricing

Office users are always free. Our subscription pricing lines up with your most valuable asset – technicians.

See PackagesOther ServiceTrade Features that Improve Fire Safety Inspection Management

Get a DemoGive technicians their schedules, inspection details, customer information, and inspection history on their devices.

Learn MoreOptimize route planning with a map-based approach to recurring inspection scheduling.

Learn MoreManage the sales process for valuable inspection agreements and present the customer with proposals that win.

Learn MoreFAQ’s

Looking for help with fire inspection software?

Fire inspection software is a tool that fire protection and life safety contractors use to inspect and manage fire alarms, fire suppression systems, and other fire equipment. Beyond digitizing paperwork, an effective software solution centralizes customer and equipment data, streamlines operations, and simplifies communications.

The right fire inspection software will help your business grow in a multitude of ways. Streamlining deficiency documentation and quoting leads to improved quote approval rates and revenue. Recording recurring inspection frequencies so you know when to schedule with the customer ensures you never miss a fire safety inspection. Online service portals and automated communications keep your customers satisfied, improve retention, and help manage your liability risk.

With ServiceTrade, technicians record deficiencies with photos, videos, audio notes, and written text and share them automatically with the office where they can quote repairs and send them to the customer—all within the application. ServiceTrade also tracks service history and open deficiencies for each piece of equipment at a facility that technicians, office staff, and customers can access at any time.

ServiceTrade is cloud-based software. Office users can use ServiceTrade on Mac and Windows computers. The technician mobile app is available on Apple and Android devices.

Fire inspectors use guided inspection forms and software to help them efficiently and accurately conduct inspections. Inspection Manager from ServiceTrade provides digital forms that walk inspectors through checking items like fire sprinklers, fire suppression systems, fire pumps, fire extinguishers, and fire alarms.

The forms are based on standards from the National Fire Protection Association and help ensure inspections comply with codes while generating documentation needed for regulators and customers. Digital NFPA inspection forms can streamline the inspection process and capture issues that may need repair.

The Latest

Helpful Resources for Selecting Fire Inspection Software

Focusing on deficiency documentation and the resulting repair revenue is a proven way to keep your business growing, even when skilled labor restraints limit your capacity. With a smart deficiency management tool and a seamless pull-through workflow, you can drive more revenue, provide a better service to your customers, and reduce your liability risk. […]

Get Started Today

See how ServiceTrade can give you control over your company’s operations.